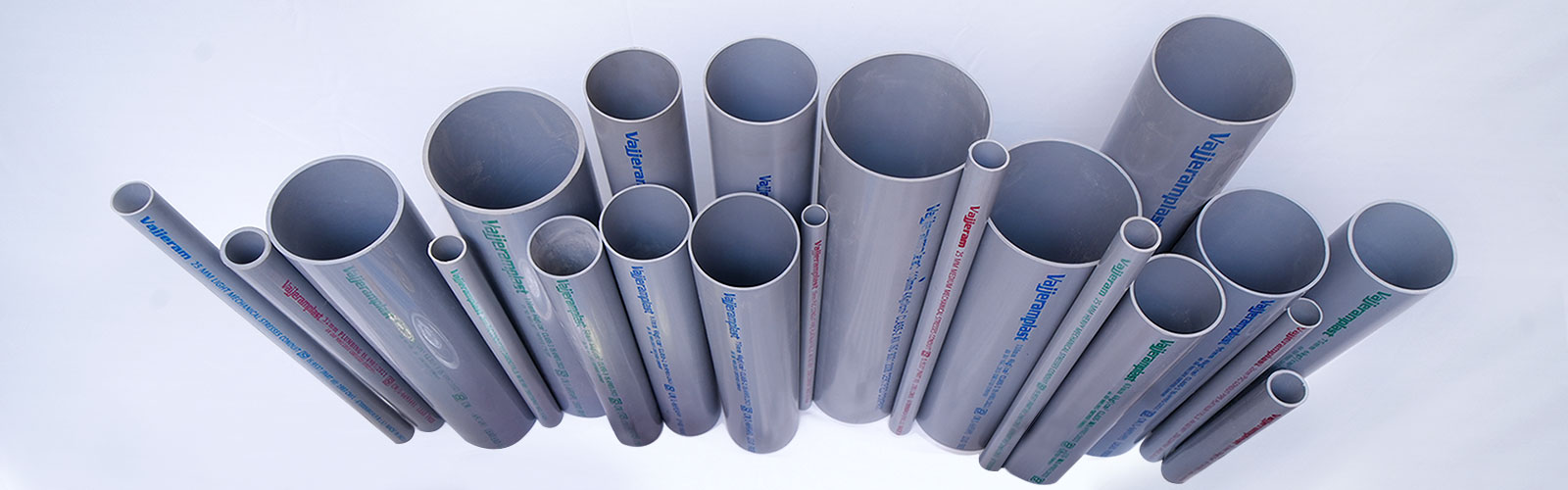

Range : 20mm to 200mm Diameter

| DIMENSIONS OF UPVC PIPES : (EXTRACT FROM IS 4985 : 2000) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean Outside Diameter (mm) | Working Pressure & Wall Thickness (in mm) | ||||||||

| Min | Max | Class 2 (4kgf cm²) |

Class 3 (6kgf cm²) |

Class 5 (10kgf cm²) |

Plumbing Pipes | ||||

| Min | Max | Min | Max | Min | Max | Min | Max | ||

| 20.0 | 20.3 | - | - | - | - | 1.1 | 1.5 | 2.8 | 3.3 |

| 25.0 | 25.3 | - | - | - | - | 1.4 | 1.8 | 2.9 | 3.4 |

| 32.0 | 32.3 | - | - | - | - | 1.8 | 2.2 | 3.4 | 3.9 |

| 40.0 | 40.3 | - | - | 1.4 | 1.8 | 2.2 | 2.7 | 3.4 | 3.9 |

| 50.0 | 50.3 | - | - | 1.7 | 2.1 | 2.8 | 3.3 | 3.7 | 4.3 |

| 63.0 | 63.3 | 1.5 | 1.9 | 2.2 | 2.7 | 3.5 | 4.1 | - | - |

| 75.0 | 75.3 | 1.8 | 2.2 | 2.6 | 3.1 | 4.2 | 4.9 | - | - |

| 90.0 | 90.3 | 2.1 | 2.6 | 3.1 | 3.7 | 5.0 | 5.7 | - | - |

| 110.0 | 110.4 | 2.5 | 3.0 | 3.7 | 4.3 | 6.1 | 7.1 | - | - |

| 140.0 | 140.5 | 3.2 | 3.8 | 4.8 | 5.5 | 7.7 | 8.9 | - | - |

| 160.0 | 160.5 | 3.7 | 4.3 | 5.4 | 6.2 | 8.8 | 10.2 | - | - |

| 180.0 | 180.5 | 4.2 | 4.9 | 6.1 | 7.1 | 9.9 | 11.4 | - | - |

| 200.0 | 200.6 | 4.6 | 5.3 | 6.8 | 7.9 | 11.0 | 12.7 | - | - |