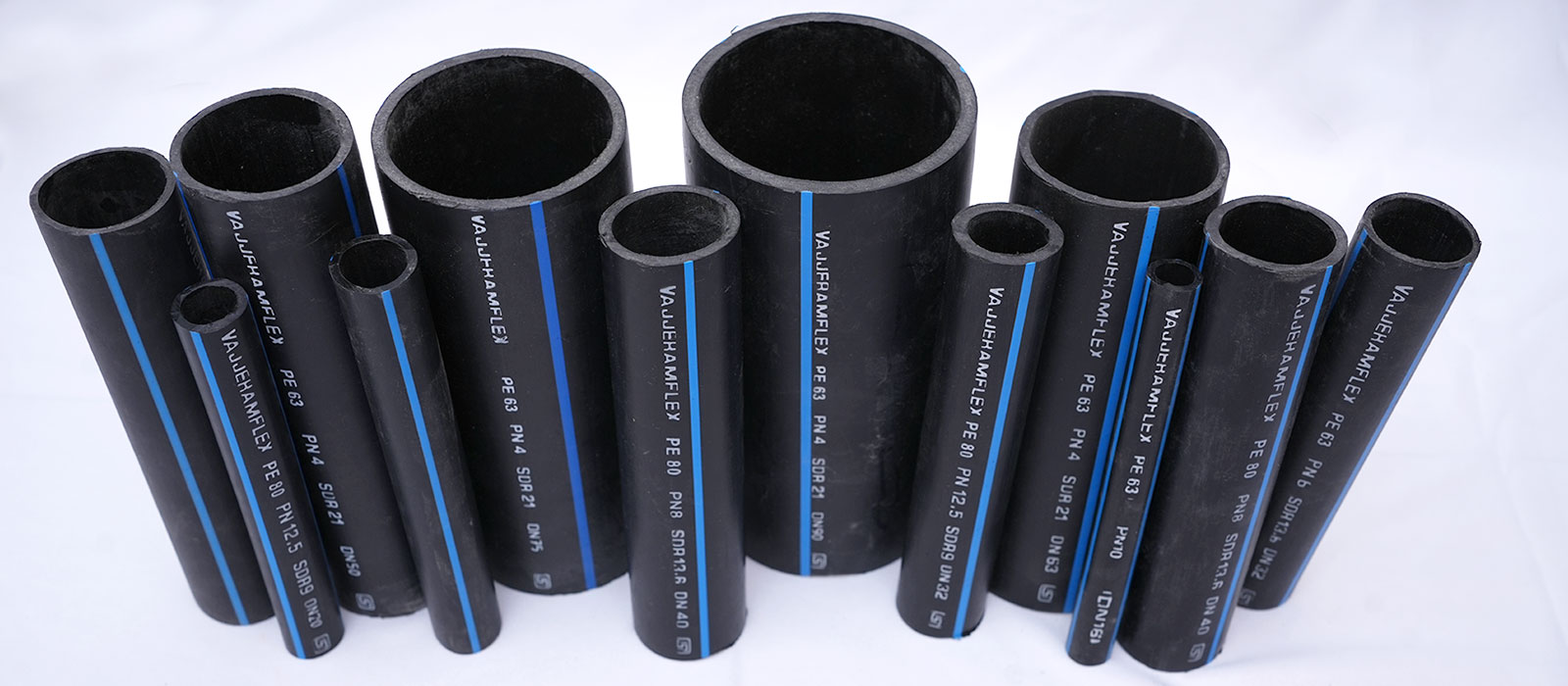

About HDPE Pipes

VAJJERAMPLAST High density polyethylene pipe has been used extensively around the world

since the 1950's.The unique properties of High density polyethylene pipe have offered an alternative

to traditional material like steel and copper and also in non pressure applications where clay and

fibre cement pipes were used.

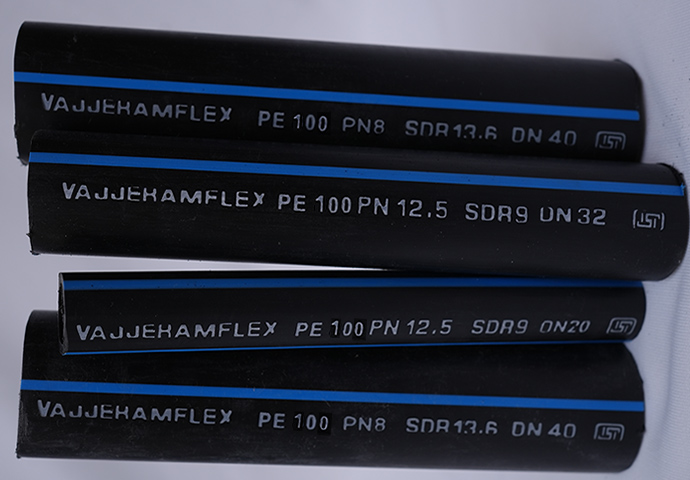

The material has been developed internationally from PE B0 to today's PE 100 material which has

shown a saving of approximately 30% on the wall thickness from the early days of Polyethylene. This

mass saving relates back to a cost saving and a better performance as the internal diameter of the

pipe is bigger. In many cases, because of the excellent flow characteristics of Polyethylene, pipes

could be down sized while still performing within the expected parameters. The pipes' properties

such as impact resistance and resistance to abrasion have made HDPE pipe the obvious choice in the

Mining and Industrial markets. Piping made from polyethylene is a cost effective solution for a broad

range of piping applications in the municipal, industrial, marine, mining, landfill, duct and agricultural

industries. It has been tested and proven effective for above ground, surface, buried, slip-lined,

floating and sub-surface marine applications. High-density polyethylene pipe (HDPE) can carry

potable water, wastewater, slurries, chemicals, hazardous wastes, and compressed gases. In fact,

polyethylene pipe has a long and distinguished history of service in the gas, ail, mining and other

industries. It has the lowest repair frequency per kilometre of pipe per year compared with all other

pressure pipe materials used for urban gas distribution. Polyethylene is a strong, extremely tough,

very durable product which offers long service and trouble-free installation.